Replacement Screen for Swaco BEM-600 / BEM-650 Shaker Screen

Anping Kangertong Company produce spare screens for MI-Swaco Mongoose shale shaker (M-I SWACO BEM-600 shaker screen, BEM-650 shaker screen and MONGOOSE PT shaker screen).

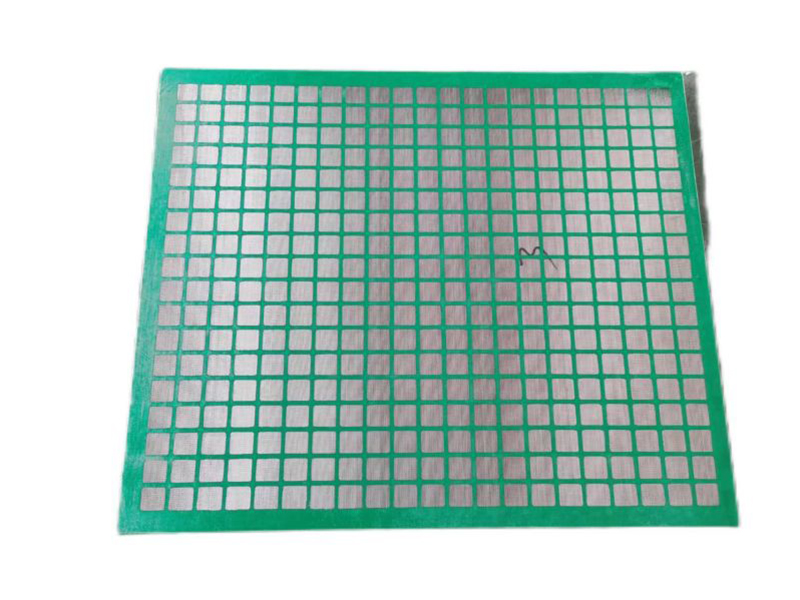

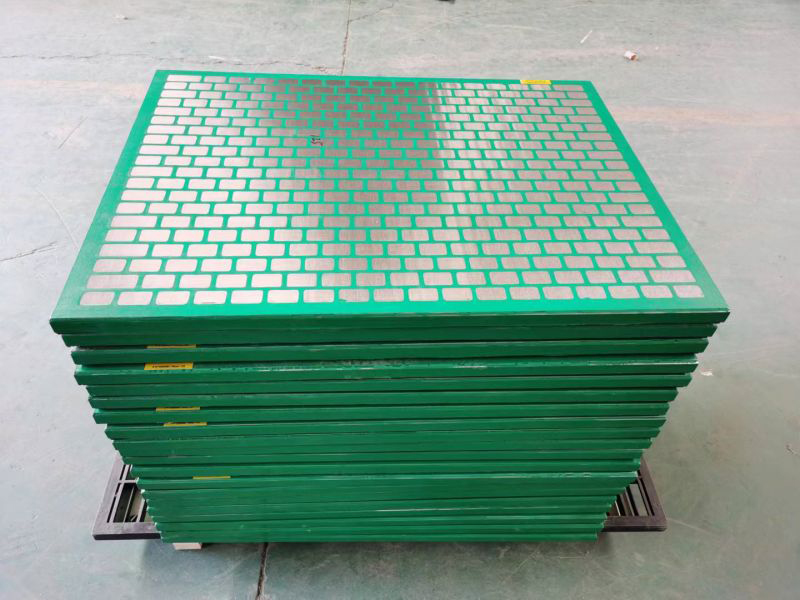

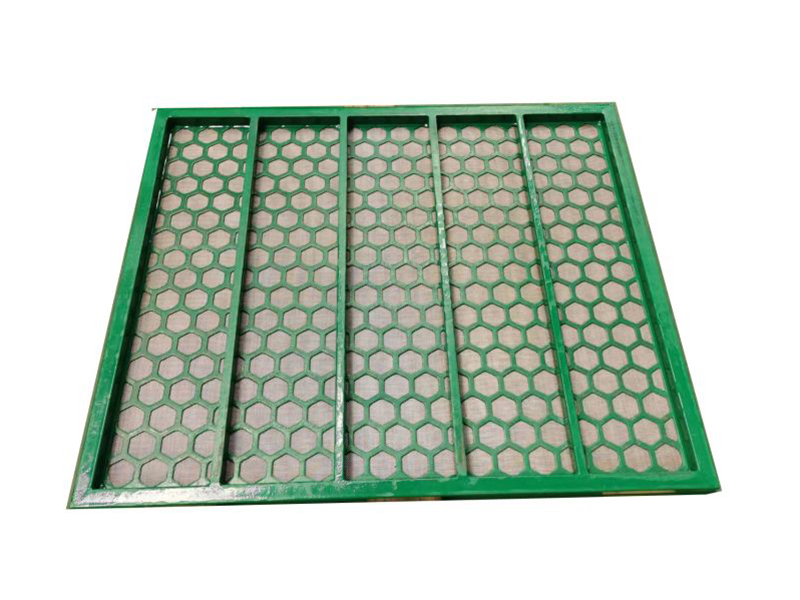

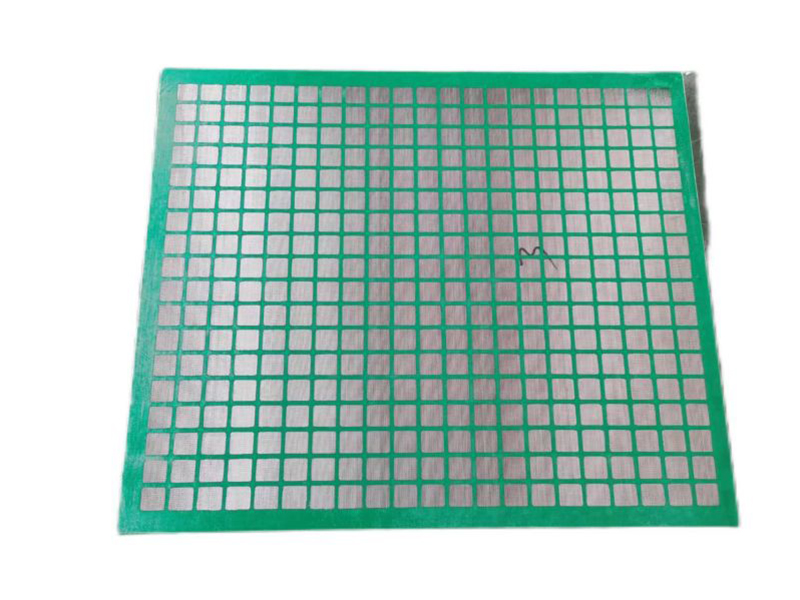

Anping Kangertong Company produce high quality replacement BEM-650 & BEM-600 series shaker screen. BEM-650 & BEM-600 is another kind of M-I Swaco shaker. The BEM-650 & BEM-600 is also pretensioned type screen. We clamp BEM-650 shaker screen via wedge blocks. It’s also quick installation shaker screen. We are studying BEM650 shaker screen and wish develop it to be composite frame screen.

Our screens for the M-I SWACO BEM-600, BEM-650 and MONGOOSE PT shale shakers offer higher throughput rates as well as longer life, lower weight, and fast, easy repair. Anping Kangertong Company replacement composite screen for M-I SWACO BEM-600&BEM-650 shale shaker takes the better balanced elliptical motion shakers on the market. Featuring composite frame design that hold up under virtually all drilling conditions, the shaker screen delivers unsurpassed usable screen area.

Higher throughput rates reduce operating costs by optimizing shaker performance, while longer frame life translates into lower screen-replacement costs. replacement shale shaker composite screens deliver even longer screen life, greater ease of repair, higher capacity and greater cost effectiveness than metal-framed and other conventional products.

Anping Kangertong Company replacement composite screen for M-I SWACO BEM-600&BEM-650 shale shaker were recommended in mesh sizes 40 to 165, having equivalent API’s of 40 to 140.

Longer screen life. The composite frame design provides more numerous panels to evenly distribute mechanical stresses. Composite screens include individually pre-tensioned mesh, which is incorporated into the composite frame. As a result, it was noted that solids were +70% drier compared to historical well data, equiating to additional operator savings from the recovery of costly drilling fluid.